The data supplied in this post is for assistance only. Not all cleanrooms will use the identical treatments. Comply with your certain cleanroom or corporation procedural handbook ahead of this guideline.

Even though there is absolutely no direct romance proven between the 209E managed ecosystem courses and microbiological stages, the pharmaceutical marketplace has been utilizing microbial concentrations comparable to these classes for several many years; and these degrees are already All those useful for evaluation of current GMP compliance.2 These levels are actually revealed to become quickly achievable with The present technology for managed environments. There have already been studies and issues about dissimilarities in these values obtained working with various sampling techniques, media variability, and incubation temperatures.

Just about every stage is consistent with employing, designing, and testing to precise necessities. Strategies for evaluation and measurements for Certification are laid out in ISO 14644-3. It requires the subsequent ten exams:

In isolators, the air enters the isolator via integral filters of HEPA high-quality or greater, as well as their interiors are sterilized commonly into a sterility assurance amount of 10

air equipped to your cleanroom is of enough quantity to dilute or take out contamination generated inside the cleanroom,

Development Evaluation—Info from the regime microbial environmental monitoring method which can be related to time, shift, facility, and so forth. This information and facts is periodically evaluated to ascertain the standing or pattern of that program to ascertain whether it is under satisfactory Manage.

General mycological media, such as Sabouraud's, Modified Sabouraud's, or Inhibitory Mold Agar are acceptable. Other media which have been validated for selling The expansion of fungi, for example Soybean&#one hundred fifty;Casein Digest Agar, may be used. Usually, tests for compulsory anaerobes is not really done routinely. On the other hand, should problems or investigations warrant, including the identification of such organisms in sterility screening amenities, more Regular tests is indicated. The flexibility of the chosen media to detect and quantitate these anaerobes or microaerophilic microorganisms needs to be evaluated.

Individual Safety and Accuracy: The final word intention of GMP cleanroom restrictions is to shield patient safety by making sure that merchandise are manufactured in environments that foster precise, productive, and repeatable effects.

Rinse Samples - Two benefits of employing rinse samples are that a larger surface area may be sampled, and inaccessible systems or kinds that can't be routinely disassembled might be sampled and evaluated.

An area in which combustible dusts or ignitable fibers and flyings are unlikely to manifest beneath usual running conditions and do this only for a brief time frame.

5 µm or more substantial. Though airborne microorganisms usually are not free of charge-floating or one cells, they frequently affiliate with particles of ten to 20 µm. Particulate counts and also microbial counts within managed environments vary Using the sampling place as well as the activities remaining executed throughout sampling. Checking the setting for nonviable particulates and microorganisms is more info a crucial Manage functionality because they equally are essential in accomplishing products compendial needs for Particulate Matter and Sterility underneath Injections

Doorway Design: To more minimize contamination pitfalls, GMP pointers stipulate that cleanroom doorways needs to be seamless, easily cleanable, and immune to cleaning agents. Sliding doorways are discouraged due to their inherent gaps and recesses which can be demanding to clean effectively.

The information gathered by more info an identification program can even be practical in the investigation in the supply of contamination, particularly when the Action degrees are exceeded.

Numerous commercially available samplers are outlined for informational uses. The choice, appropriateness, and adequacy of applying any particular sampler is the duty from the user.

Ariana Richards Then & Now!

Ariana Richards Then & Now! Molly Ringwald Then & Now!

Molly Ringwald Then & Now! Andrew Keegan Then & Now!

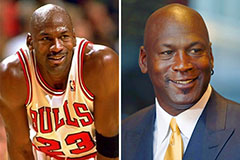

Andrew Keegan Then & Now! Michael Jordan Then & Now!

Michael Jordan Then & Now! Andrew McCarthy Then & Now!

Andrew McCarthy Then & Now!